Soluble potassium silicate, additionally known as fluid glass, is a multifunctional substance used in different industries, including building, farming, and manufacturing. This article will look into the attributes, manufacturing processes, makes use of, and ecological advantages of soluble potassium silicate, using readers a thorough understanding of its value.

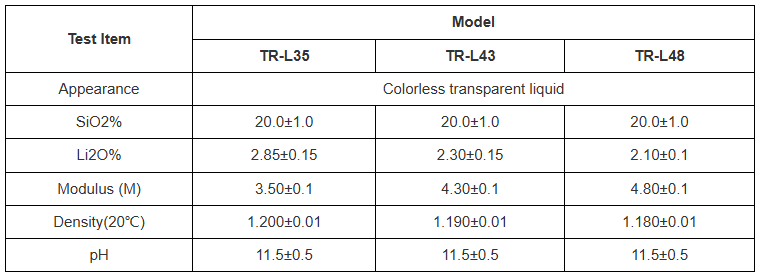

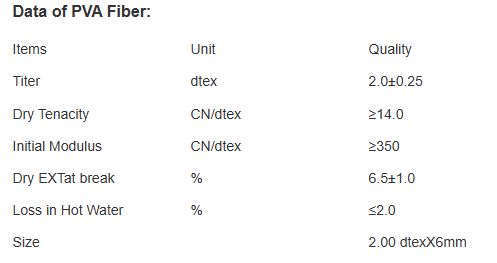

(Parameters of Potassium Silicate)

What is Soluble Potassium Silicate?

Soluble potassium silicate is a clear, alkaline option made up of potassium oxide (K ₂ O) and silicon dioxide (SiO ₂). It is generated by reacting potassium carbonate with silica at high temperatures, followed by liquifying the item in water. Soluble potassium silicate is known for its exceptional binding, adhesive, and protective buildings, making it an important additive in several formulations.

Quality and Perks

Soluble potassium silicate possesses several key buildings that make it a versatile additive:

1. Binding and Adhesive Qualities: Soluble potassium silicate functions as a solid binder and glue, improving the structural integrity of products.

2. Safety Finish: It creates a safety layer that stands up to water, chemicals, and UV radiation, prolonging the lifespan of surface areas.

3. Fire Retardant: Soluble potassium silicate can be made use of as a fire retardant, decreasing the flammability of products.

4. pH Stabilizer: It helps support the pH of formulas, guaranteeing constant performance.

5.Non-Toxic and Eco-Friendly: Soluble potassium silicate is non-toxic and eco-friendly, making it safe for both human use and the atmosphere.

Production Methods

The production of soluble potassium silicate includes the complying with actions:

1. Reaction: Potassium carbonate (K ₂ CO ₃) is responded with silica (SiO ₂) at heats to create potassium silicate.

2. Dissolution: The resulting potassium silicate is dissolved in water to create a clear, alkaline remedy.

3. Purification and Filtration: The solution is filteringed system and cleansed to remove pollutants, making sure a high-grade final product.

Applications

Soluble potassium silicate is commonly used in numerous industries due to its distinct properties:

1. Building: Used in concrete admixtures, sealants, and fireproofing products to boost strength, resilience, and fire resistance.

2. Farming: Applied as a foliar spray to enhance plant wellness and resistance to parasites and conditions.

3. Production: Made use of in the production of paints, finishes, and adhesives to improve their efficiency and sturdiness.

4. Water Therapy: Used in water treatment processes to clarify and cleanse water.

5. Textile Sector: Used in the completing of textiles to enhance their stamina and resistance to wear and tear.

Environmental Advantages

Soluble potassium silicate provides a number of environmental advantages:

1. Biodegradability: It is readily naturally degradable, decreasing its environmental impact.

2.Non-Toxic: It is safe and risk-free for both humans and the environment.

3. Sustainable: Its usage in numerous applications advertises sustainability and lowers the demand for harmful chemicals.

Use Measures

While soluble potassium silicate is generally safe to utilize, the following preventative measures should be observed:

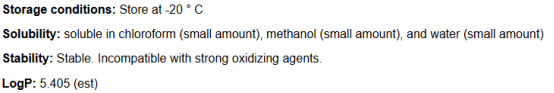

1. Storage: Store in a cool, dry location away from straight sunshine to keep its security.

2. Handling: Usage suitable personal safety equipment (PPE) when taking care of to avoid skin and eye get in touch with.

3. Disposal: Dispose of soluble potassium silicate and its containers according to regional regulations to reduce ecological effect.

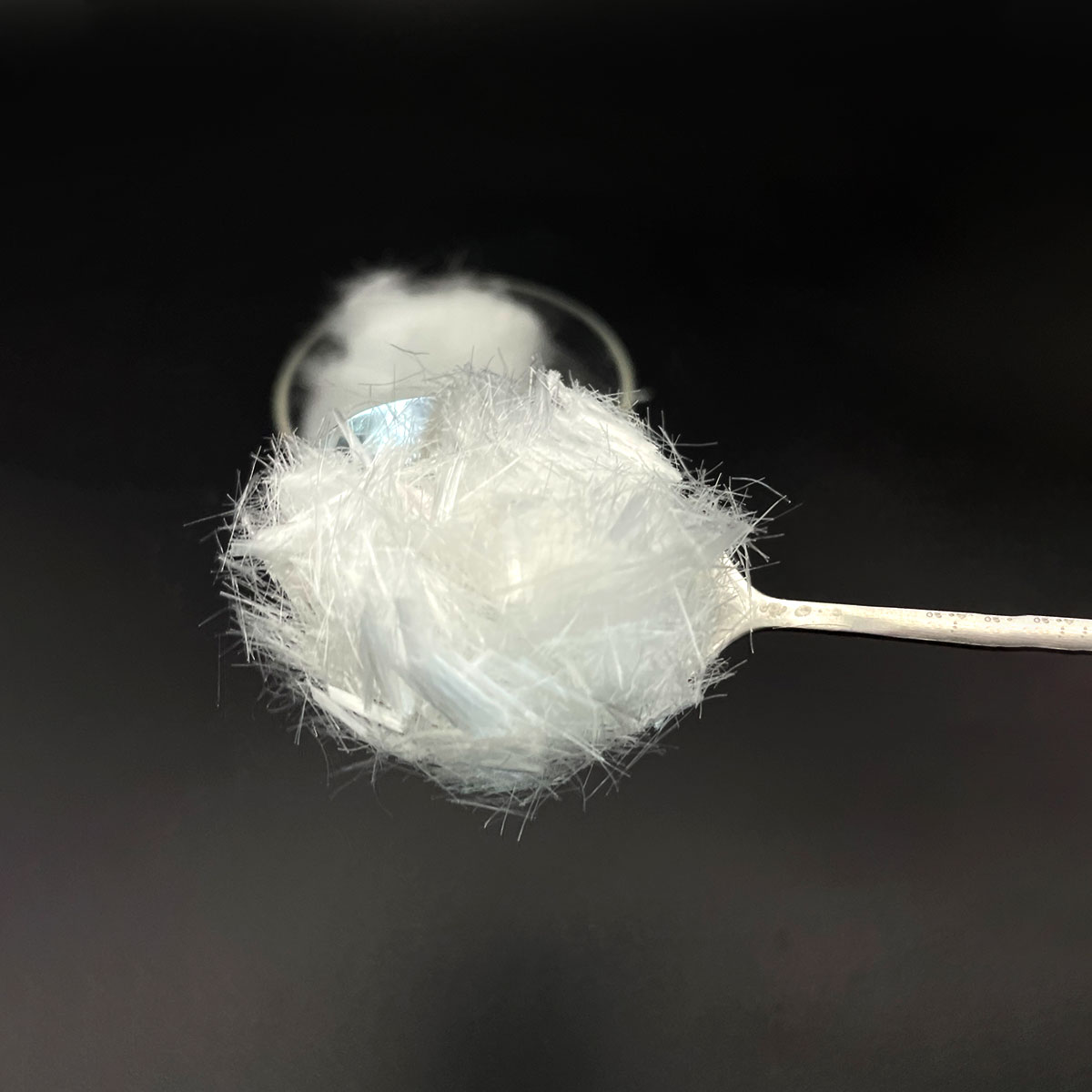

(TRUNNANO Potassium Silicate)

Market Prospects and Advancement Trends

As the need for eco-friendly and lasting products remains to expand, the marketplace for soluble potassium silicate is expected to increase. Innovations in manufacturing approaches and solution innovations will better enhance its efficiency and adaptability, opening up new applications in different industries. Future growths might consist of:

1. Enhanced Performance: Optimization of soluble potassium silicate formulas to enhance binding, safety, and fire-retardant residential properties.

2. New Applications: Exploration of new applications in arising industries, such as environment-friendly chemistry and biotechnology.

3. Sustainability: Continued focus on sustainable production approaches and environmentally friendly solutions.

Final thought

Soluble potassium silicate is a functional and eco-friendly additive with a wide variety of applications. Its excellent binding, safety, and fire-retardant buildings make it a useful component in building and construction, agriculture, and production. As the demand for lasting items grows, soluble potassium silicate is positioned to play a significantly crucial role in different sectors. This short article aims to provide valuable insights for specialists and motivate further innovation in making use of soluble potassium silicate.

Top Notch Potassium Silicate Provider

TRUNNANO is a supplier of Potassium Silicate with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about potassium silicate, please feel free to contact us and send an inquiry(sales5@nanotrun.com).

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us